Extraction of hydrocarbons

Extraction of hydrocarbons

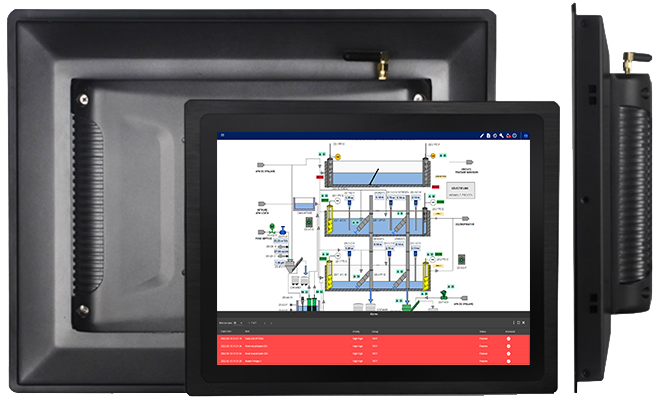

Remote monitoring of the operation of hydrocarbon extraction wells in the oil field: vibration analysis, energy consumption, extracted quantities, etc.

What were we monitoring?

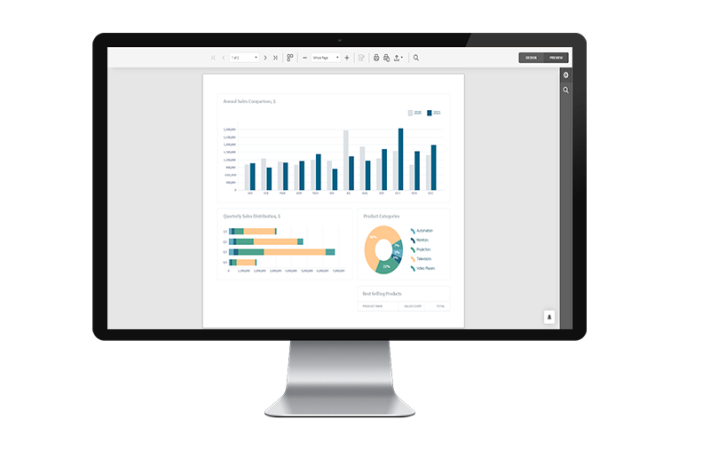

1. Oil purity monitoring

80% of defects are based on the phenomenon of abrasive mechanical wear caused by lack of lubrication or incorrect lubrication.

tracking and limiting the phenomenon of abrasive wear is done by monitoring and reducing the number of particles in the oil.

water and air in the oil exponentially amplify the phenomena of mechanical abrasion wear.

maintaining the lubricant in a correct degree of purity and humidity is the main preventive means of mechanical maintenance.

2. Vibration monitoring.

90% of mechanical defects are manifested by the appearance of a vibrating regime that amplifies with the amplification of the defect.

monitoring the vibratory regime of a mechanical assembly can detect the appearance of a defect from the very beginning.

vibration analysis is the main means of establishing corrective measures in a system (the defective part is located and replaced before a chain reaction effect, disastrous in the long term, occurs).

3. The purity and humidity of the oil

Using an HDU system from CC Jensen with a high filtration fineness (3μm absolute) and an increased retention capacity (4kg impurities/filter element)