Automotive

Automotive

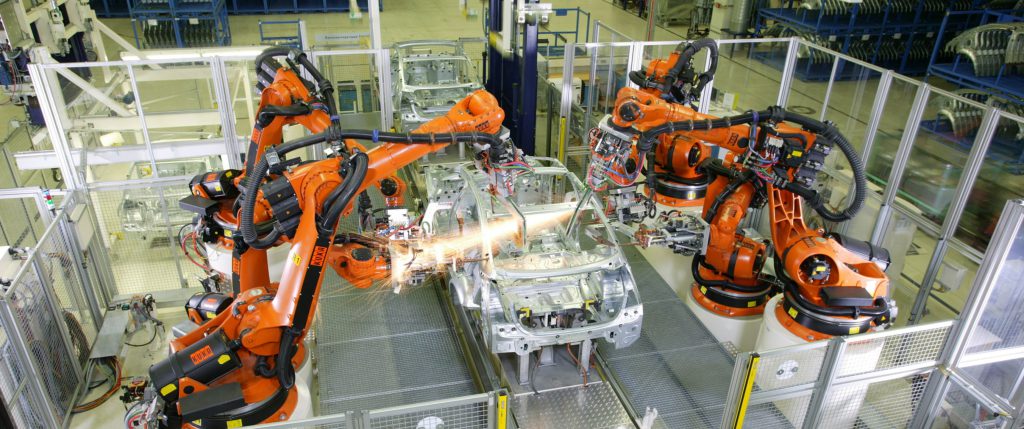

Automation is already widely used in the automotive sector and in addition to industrial robots used in manufacturing processes, we also mention the MP400 presses integrated in the manufacturing processes of profiles based on molds.

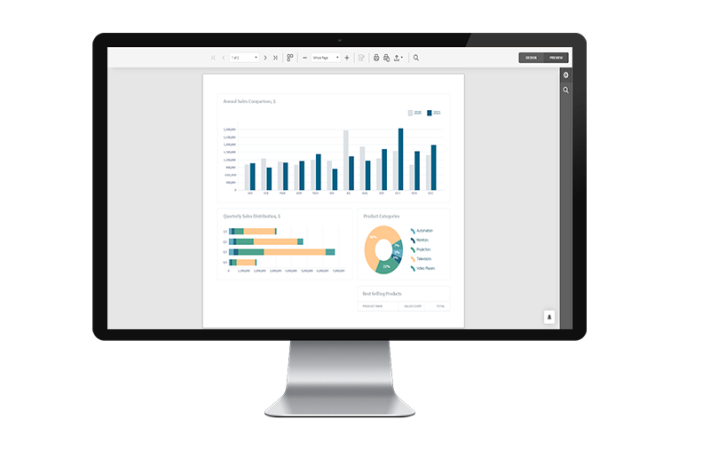

Older automated systems produce dead work times and implicitly financial losses, considering that related production lines can stop due to the defects of obsolete components. Their purchase is becoming more and more difficult considering that they are no longer manufactured over time. In addition, their replacement or reprogramming requires a long and expensive process. The malfunction of the technological process far exceeds the cost of replacing the faulty system.

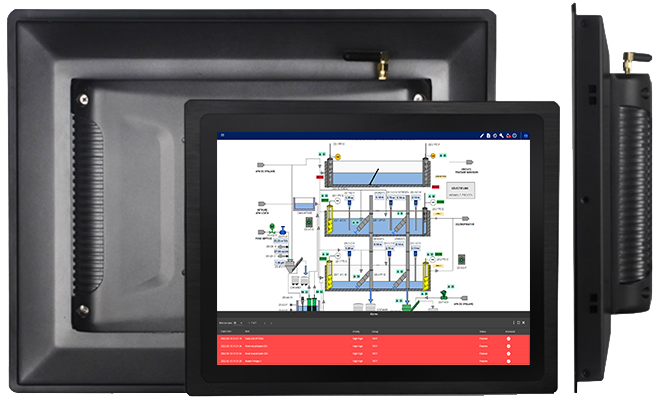

The services we offer cover the replacement and reprogramming of old automation systems such as PLC/SCADA/ HMI. WEBICC SCADA is the perfect solution for monitoring technological parameters considering the multitude of communication protocols it contains. We acquire the operating logic of the existing technological process and transpose it into the new automation system with the necessary new improvements.